3D printed ceramic ink can absorb harmful chemicals and acid from the water supply

University of Bath produces 3D printed monolith from ceramic ink

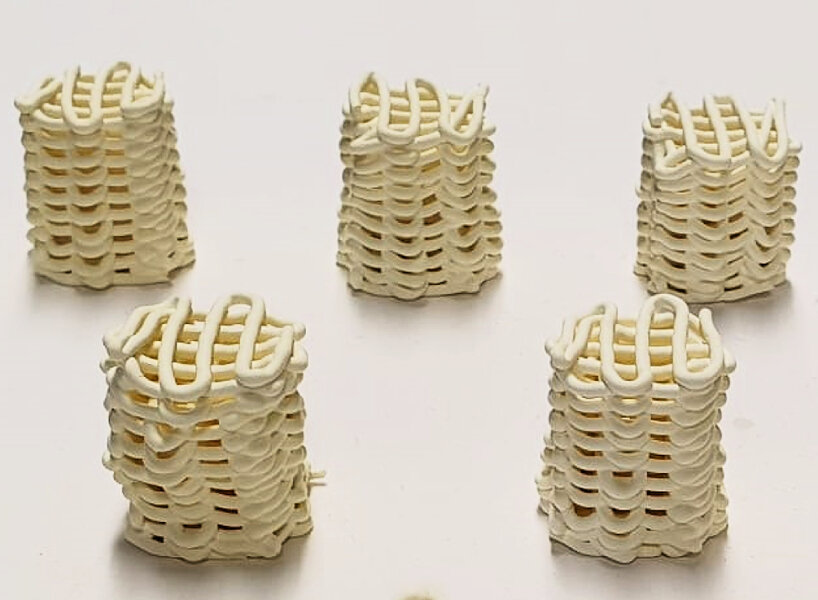

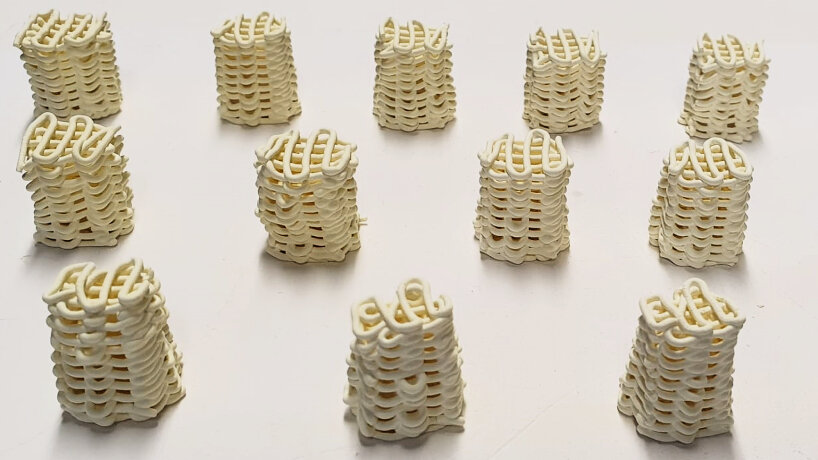

Engineers from the University of Bath turned to 3D printing to remove the so-called “perpetual chemicals” from the water supply. With this technology they have Ceramics-infused grids or “monoliths” that can remove at least 75 percent of perfluorooctanoic acid (PFOA) from water, among other things. These 3D-printed structures are made of ink mixed with ceramic indium oxide, which can bond with the acids in the water. A 3D printer squeezes out this formula and forms a grid structure, creating the monoliths.

The engineers say that chemicals in water supplies and bodies will instantly stick to these 3D printed structures, allowing them to be removed from them, due to the indium oxide and its ability to bind acids. The team adds that the process can be completed in under three hours and that this study and method are compatible with current water treatment plants in the UK and abroad. If the 3D printed ceramic ink proves successful, it could help eliminate harmful chemicals in water.

All images courtesy of the researchers and the University of Bath

Ceramic ink can remove up to 75 percent of chemicals

After testing the Researchers have found that their 3D printed ceramic ink can remove up to 75 percent of harmful chemicals from the water supply. These monoliths actually become more effective at soaking up these perfluorooctanoic acids the more frequently they are used. This is because the filters undergo a high-temperature cleaning process after each use, which appears to improve their performance. The next step for the researchers is to study why the chemical filters work better each time they are used, so they plan to do more testing to find out.

“Making the monoliths using 3D printing is relatively easy and that also means that the process should be scalable. Once the monoliths are ready, you just drop them into the water and let them do their work. That’s very exciting and something we would like to develop further and experience in practice,” says Dr. Liana Zoumpouli, Research Associate in the Department of Chemical Engineering in Bath and member of the Centre for Digital Manufacturing and Design.

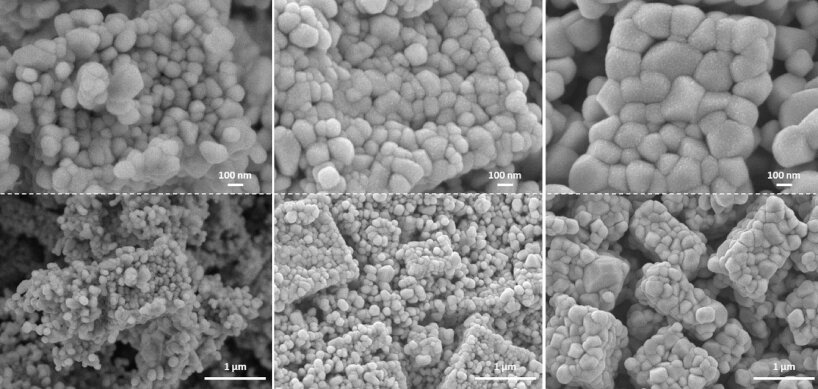

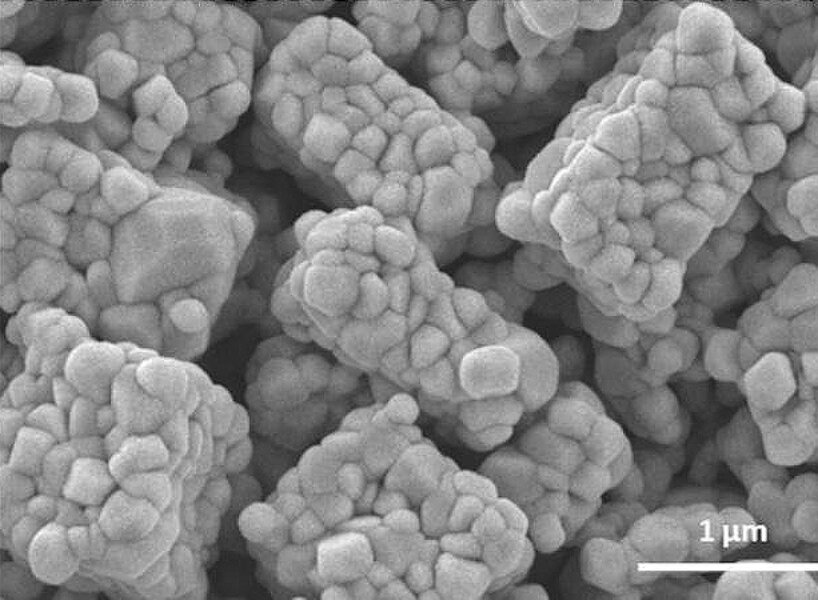

Microscopic view of indium oxide in 3D printed ceramic ink monolith | Image via Science Direct

3D printed monoliths to accelerate chemical degradation

Some countries, particularly the United States and Europe, already have regulations in place about how much perfluorooctanoic acid can be in drinking water and other supplies. It is one of the most common perfluorinated and polyfluorinated alkyl substances (PFAS), and even if regulations already exist, scientists say they may not be sufficient given the health hazards these chemicals pose. They add that stricter laws or regulations are likely to be introduced in the future to better protect people from these health risks.

These substances are called “forever chemicals” because they take a long time to break down. In some cases, this process can take over 1,000 years. These perfluoroalkyl and polyfluoroalkyl substances are man-made. They are known to be harmful to reproductive and developmental processes, the cardiovascular system, and increase the risk of diabetes. Sources of these substances include household products, often with water-repellent properties, such as non-stick pans, raincoats, paints, fabrics, and fire-fighting foams.

Detailed view of indium oxide in the 3D printed ceramic ink monoliths

These structures can remove up to 75 percent of harmful chemicals from the water

Project info:

Name: 3D printed ceramic ink

Researchers: Dr. Alysson Martins, Dr. Liana Zoumpouli, Dr. Antonio Jose Exposito, Dr. Jannis Wenk, Professor Davide Mattia

Institution: University of Bath | @uniofbath

Study: Here

Matthew Burgos | Design Boom

22 August 2024