Manganese nanoparticles can increase global drinking water availability by more than 2.5%, scientists say

“The importance of this project lies in its potential to revolutionize water treatment processes and deliver technological, economic, environmental and health benefits on a large scale.”

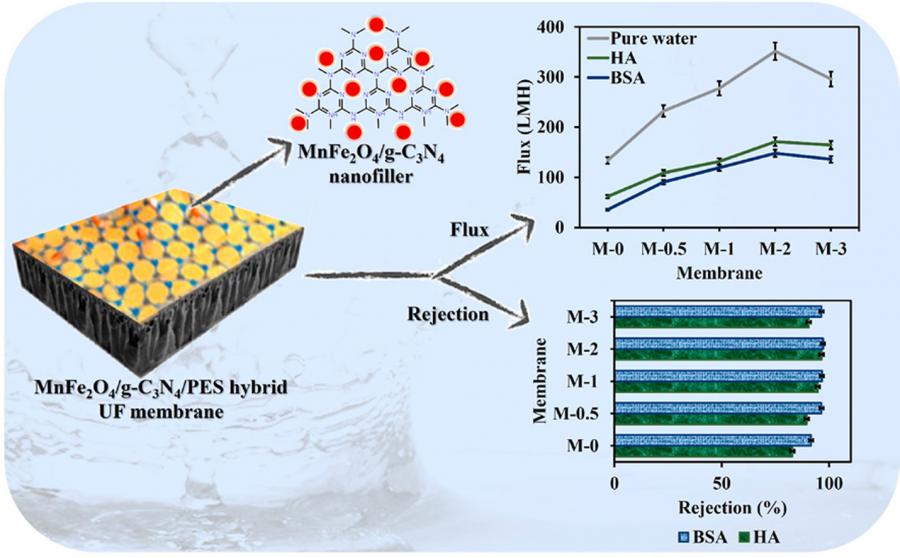

Graphical representation of (a) the preparation of the MnFe2O4/g-3N4 nanocomposite, (b) the fabrication of MnFe2O4/g-C3N4/PES hybrid UF membranes by NIPS, and (c) the dead-end cell filtration setup used for filtration experiments.

SHARJAH, EMIRATE SHARJAH, UNITED ARAB EMIRATES, August 26, 2024 /EINPresswire.com/ – Manganese ferrite nanoparticles could lead to a significant increase in drinking water availability worldwide if used to modify the filter layers currently used in water treatment plants, scientists say.

“Our study records some exceptional results. The best performing membrane, containing 2 weight percent composite material, achieved a water flux of 351.4 LMH, which is 2.6 times higher than the original PES membranes,” said study co-author Dr. Ismail Almanassra, a research fellow at the Institute of Science and Technology, University of Sharjah.

PES or polyethersulfone membranes are essential for water treatment plants because they act as barriers that allow drinking water to pass through and prevent unwanted substances from entering. They filter salts, contaminants and other unwanted particles from the water.

“The importance of this project lies in its potential to revolutionise water treatment processes and deliver technological, economic, environmental and health benefits on a large scale,” added Dr Almanassra.

The study, published in the Journal of Membrane Science, shows that the scientists have developed “UF membranes with superior water flux and rejection rates” and are able to address key inefficiencies in current water treatment methods. (Original source URL: https://www.sciencedirect.com/science/article/pii/S0376738823009158?casa_token=lYRCx_NlIE0AAAAA:5aAxuFkv1hTHUsFZsGu9PQ1mngIdlCzmHP7vIHzVcrh0k7IWvPY5aHHO6gltOG5TLJDSiM5qDWCV)

“The project effectively reduces biofouling, lowers maintenance and operating costs, while contributing to environmental sustainability through more efficient water management,” added Dr. Almanassra.

UF or ultrafiltration membranes are widely used in water treatment plants around the world. They are also commonly used in desalination projects, as well as for groundwater pretreatment, food processing, industrial chemical separation and wastewater treatment.

UF membranes also act as a barrier to suspend endotoxins, viruses and other solids and pathogens, producing drinking water with high purity and low sludge density. They are usually made of polymer materials or ceramics.

Dr. Almanassra said that water treatment and desalination plants currently face several challenges, “especially during the pretreatment phase where polymer-based ultrafiltration (UF) membranes are used for decontamination.”

“A major problem is biofouling, where biological materials accumulate on the membrane surface and negatively affect permeate flux and water quality.”

Biofouling affects the efficiency and durability of UF membranes used in water treatment plants. It is caused by microorganisms that pollute and contaminate the water, reduce potable water production, and cover, block or damage membrane surfaces.

This is a problem that plant engineers still struggle with. To solve it, they typically take two approaches. The first involves increasing the operating pressure on FU membranes to maintain permeability and water production. The second requires them to frequently replace biofouled membranes.

However, the study authors show that both solutions result in higher operating and maintenance costs. As researchers with diverse backgrounds, they work on innovating and developing UF membranes by integrating hydrophilic materials to effectively combat biofouling and reduce long-term costs.

“This approach not only improves permeate flux and contaminant removal rates, but also significantly reduces the impacts of biofouling over time, resulting in more efficient and cost-effective water treatment solutions,” said Dr. Almanassra.

The scientists’ innovation lies in their success in modifying 2D graphite carbon nitride with manganese ferrite nanoparticles to be used as nanofillers for PES-UF membranes. The membranes were prepared with different mass loadings of the additive between 0.5 and 3 wt% using the phase inversion method.

Prior to testing and evaluation, these films were characterized using various techniques to investigate their morphology, surface roughness, and physicochemical and mechanical properties. The membranes were then tested with fouling agents known to cause fouling over time.

“In terms of rejection and antifouling capacity, our membrane was outstanding, rejecting over 95% of HA and BSA. Impressively, the membrane maintained a recovery rate of over 88% even after hydraulic cleaning.

“The integration of hydrophilic materials represents a significant advance in materials science, with potential applications beyond water treatment. Ultimately, this project improves public health by providing cleaner, safer water and offering scalable solutions to the global challenges of water scarcity and pollution.”

LEON BARKHO

University of Sharjah

971501654376

Send us an email here

Disclaimer:

EIN Presswire provides this news content “as is” without any warranty of any kind. We do not assume any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, please contact the author above.

![]()